Download our product information sheets: Rope Cutters | Flexible Engine Mounts | Damper Drive Plates | Flexible Shaft Couplings | Clamp Half Couplings, Adaptors & Bobbins

UK Office Opening Hours: Monday - Friday: 8:00am - 5:00pm | Saturday & Sunday: Closed

Published on July 15, 2025

A failing gearbox doesn’t just cause downtime; it can result in serious repair bills, lost sailing time, and unnecessary headaches. But what if the reason behind isn’t the gearbox itself? In many marine engine failures, the issue is something small, hidden, and often overlooked: the marine damper drive plate

Marine propulsion systems face constant torsional vibrations, those pulses and twists generated as power is transmitted from the engine to the gearbox. If left unmanaged, these vibrations can cause gearbox chatter, spline wear, and even total drivetrain failure.

That’s where a damper plate for marine gearboxes comes in. It’s a vital part of your engine’s vibration control system, protecting components and keeping your ride smooth.

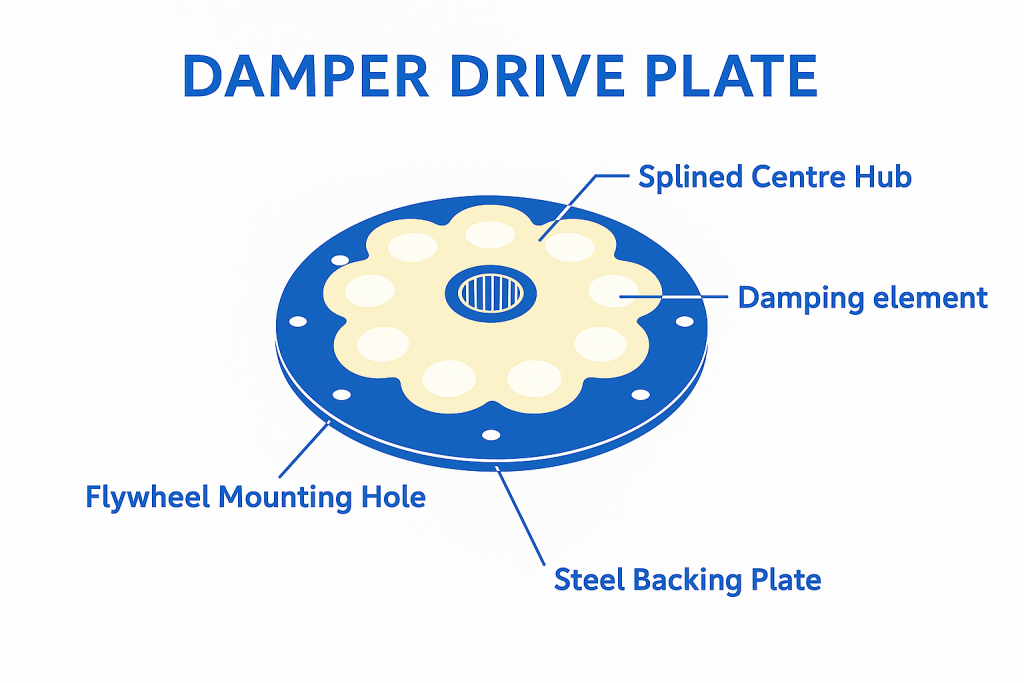

Think of it as a shock absorber for your gearbox, but far more critical. A marine damper drive plate is a flexible coupling plate that connects the flywheel of a marine diesel engine to the input shaft of a marine gearbox.

Its primary job is to absorb torsional vibrations before they reach the gearbox, helping to reduce gearbox noise, wear, and the risk of failure.

Here’s what it consists of:

Together, these elements create a semi-flexible, fail-safe damper plate that stabilises the transfer of power.

Not all marine engines are the same, and neither are their damper plates. The right marine damper plate depends on your boat’s power output, engine type, gearbox model, and how the vessel is used.

Let’s break down the most common marine damper plate types and where each fits best.

Best for: Light-duty leisure boats, day cruisers, sailboats with auxiliary diesels

Typical Gearboxes: PRM 80 / PRM 120

Features Include

If you own a small leisure vessel or weekend cruiser with a diesel engine and PRM gearbox, this is likely the damper plate you need. It provides basic marine engine vibration control and works reliably in balanced load scenarios.

Best for: Commercial fishing boats, diving charters, vessels with variable load and speed

Typical Gearboxes: PRM 260 / PRM 500 / ZF 25M

Features Include

Ideal for workboats that regularly switch between full throttle and low-speed manoeuvring. The three-stage damping action ensures the plate can adjust to varying loads without compromising gearbox safety.

Best for: Trawlers, tugboats, survey vessels, and displacement hulls

When your marine diesel engine powers through demanding environments, this is your go-to. It offers unmatched durability in extreme torsional vibration scenarios, often experienced in larger, slower-moving commercial vessels.

Features Include

Below is a simple comparison of the three main marine damper plate types, designed to help you quickly identify what suits your setup.

| Type | Max Deflection | Damping Element | Reversible Drive | Best Use Case |

| Loop | 5° | Spring-steel loop | Yes | Leisure craft, weekend cruisers |

| Hammer Head | Up to 9° | Three-stage metal head | Yes | Fishing boats, dive boats, and commercial use |

| High-Deflection | Up to 30° | Polyester elastomer | One-way only | Workboats, tugs, trawlers, and heavy-duty tasks |

A damper plate for marine gearboxes is a mechanical buffer. It’s bolted directly to the engine flywheel and splined onto the input shaft of the gearbox. But it doesn’t just transfer power, it absorbs vibration, smooths out torque pulses, and protects sensitive gearbox components from wear and tear.

The damper plate sits between the flywheel and gearbox input shaft, creating a strong but flexible link.

As your marine diesel engine generates power, it naturally creates torsional vibrations – tiny rotational jolts. The damper plate acts like a cushion, absorbing these pulses before they reach the gearbox.

Whether it’s a spring loop, a hammer, or an elastomer puck, the damping medium flexes to absorb stress. The more demanding the conditions, the more the plate deflects, protecting everything downstream.

Without damping, these vibration spikes can cause spline wear, premature seal failure, or cracks in the gearbox casing. The damper plate absorbs the shock, saving your gearbox from damage.

Lightweight flywheels, common in modern marine engines, tend to produce gearbox chatter at idle. The damper drive plate minimises this noise, resulting in a quieter, smoother experience.

A quality damper drive plate marine setup helps align torque delivery during gear changes, making shifting less clunky and more fluid, especially in tight harbours or when trolling.

Wherever marine engines meet gearboxes, a damper plate could genuinely make – or – break the system. These components play a huge role in ensuring your marine propulsion drivetrain runs smoothly, quietly, and reliably.

If you’re out enjoying a cruise along the coast, the right marine damper drive plate can be the difference between a peaceful voyage and costly mechanical headaches.

Let’s explore the real-world marine applications where these plates shine.

These vessels typically operate under steady loads and demand comfort, efficiency, and long-term reliability.

Loop-type or hammer-head damper plates are ideal here, offering reliable marine engine vibration control and protecting your gearbox from chatter and early wear.

When you’re out trolling for hours at low speed, your engine is producing lots of irregular, low-frequency pulses.

Perfect for vessels with ZF marine damper plate setups or heavier Hurth gearboxes used in traditional diesel fishing craft.

Think ferries, harbour charters, sightseeing boats, any craft that regularly shifts gears under load.

If you operate in tight quarters or busy ports, this setup ensures your damper plate for the marine gearbox keeps everything running smoothly and safely.

It’s not just propulsion systems that need help. Marine gensets and auxiliary engines also benefit from damper plates.

Operating a tug, trawler, or survey vessel? These workhorses run high-torque marine diesel engines and need custom damping solutions.

If your engine ticks any of these boxes, your gearbox might be at risk, unless you’re using the right damper. Over 80% of gearbox failures are caused by unmanaged torsional vibrations.

A damper plate isn’t something you notice until it fails, or isn’t fitted. But just because it’s hidden doesn’t mean it’s optional. Here are the most common scenarios where a marine damper drive plate becomes critical to your engine’s health and your boat’s reliability.

If your vessel spends a lot of time trolling or idling, say you’re out fishing for hours, you’re especially vulnerable to gearbox chatter.

A damper plate helps dampen vibration at low RPMs, protecting gearbox internals from premature wear and noise. It also keeps the engine running quieter, improving onboard comfort.

Diesel engines naturally produce more torsional vibration at low speeds. That means without damping, you get jerky torque delivery to the gearbox.

The flywheel to gearbox connection becomes stressed, causing fatigue over time. A damper plate acts as a cushion, preserving the longevity of your system.

If you hear a knocking or clanking sound when idling or engaging gears, then that’s not “normal”; it’s a classic sign of a failing marine damper plate or the lack of one altogether.

In such cases, installing a suitable gearbox damper marine solution can eliminate that noise instantly and prevent damage.

Newer marine diesels are built lighter to reduce fuel consumption, but that comes at a cost.

Less inertia leads to more vibration being transferred to the gearbox. This is where a PRM damper plate or ZF marine damper plate, specifically tuned for the engine setup, becomes essential.

If you’re upgrading your gearbox, it’s the perfect time to add or upgrade the damper plate, too.

If you run a tugboat, pilot boat, or offshore supply vessel, you know how demanding it can be on your gear.

Fluctuating torque during sudden acceleration or hull resistance can create massive strain on your drivetrain. A high-deflection elastomer coupling damper plate can safely handle this shock, keeping everything intact and operable.

Ultimately, that’s what it’s all about. A marine damper drive plate:

The marine damper drive plate might not be the flashiest component in your engine bay, but it’s one of the most important.

From absorbing torsional vibrations and reducing gearbox rattle to preventing costly failures and improving overall system longevity, it serves as the first line of defence in your marine propulsion drivetrain.

If your vessel matches any of the signs we’ve covered, frequent idling, low-RPM operation, lightweight engines, or gear chatter, it’s time to inspect, install, or upgrade your damper plate.

Do you need help choosing the right model? Contact R&D Marine for expert guidance, UK-manufactured components, and quick dispatch on everything from PRM damper plates to tailored options for ZF gearboxes.

When it comes to protecting your marine gearbox and ensuring smooth, reliable propulsion, don’t settle for guesswork or generic parts. Choose expertise and precision with R&D Marine.

As a globally trusted supplier of marine damper drive plates, R&D Marine is the go-to partner for boatbuilders, engineers, and skippers, backed by UK-based engineering and global distribution. We’ve been doing this for decades, and we’ve earned the trust of leading OEMs and gearbox manufacturers, including PRM, ZF, Hurth, and Technodrive.

If you need a robust damper plate for a weekend cruiser or a high-deflection solution for a commercial vessel running a ZF gearbox, we’ve got the engineering knowledge and product range to deliver.

And it’s not just damper plates. We also supply:

If you need help selecting the right marine damper drive plate, our team is just a phone call away. Call us on 01462 892391 for personalised advice, gearbox compatibility checks, and current stock availability.

Yes, particularly in diesel-powered setups. Without a damper plate for marine gearbox applications, your gearbox is exposed to the full force of the engine’s torsional vibrations. These vibrations can cause excessive wear on the input shaft, lead to gearbox chatter, and even result in spline damage or failure over time. Many modern gearbox manufacturers like PRM and ZF now require the use of a damper plate to maintain warranty coverage. It’s a vital component, not an optional extra.

On average, a quality marine damper drive plate will last between 5 to 10 years, depending on your vessel type, usage hours, and engine load. Commercial vessels that run continuously or frequently troll at low RPM may experience faster wear than occasional leisure cruisers.

It is recommended to perform a visual inspection every 500 engine hours or during routine servicing. Look for cracks in the damping material, distortion in the hub, or signs of spline wear.

A worn or broken damper plate can manifest in a few clear warning signs:

If you’re experiencing any of these symptoms, it may be time to inspect or replace the damper plate before more serious damage occurs.

Start with this basic formula to calculate torque:

Torque (lb.ft) = (Horsepower × 5250) ÷ RPM

Once you’ve calculated your engine’s torque, you can:

Still not sure? Just call us at 01462 892391 and our experts will walk you through it.

While the actual damper drive plate installation is mechanically straightforward, usually requiring just a few bolts, proper gearbox alignment is critical. If the plate isn’t perfectly aligned to the flywheel to gearbox connection, it can cause vibration, excessive wear, or even failure. Experienced DIYers or technicians may feel comfortable doing the job, but if you’re unsure, it’s best to consult a qualified marine engineer to ensure everything runs true.

The gearbox takes the hit. Without a damper plate vibration-damping system, the torsional vibration in marine engines is transferred straight to the gearbox. This leads to: